Edwards nXDS20iR Oil-Free Dry Scroll Vacuum Pump. PN: A73803983

$10,147.11 $11,495.61

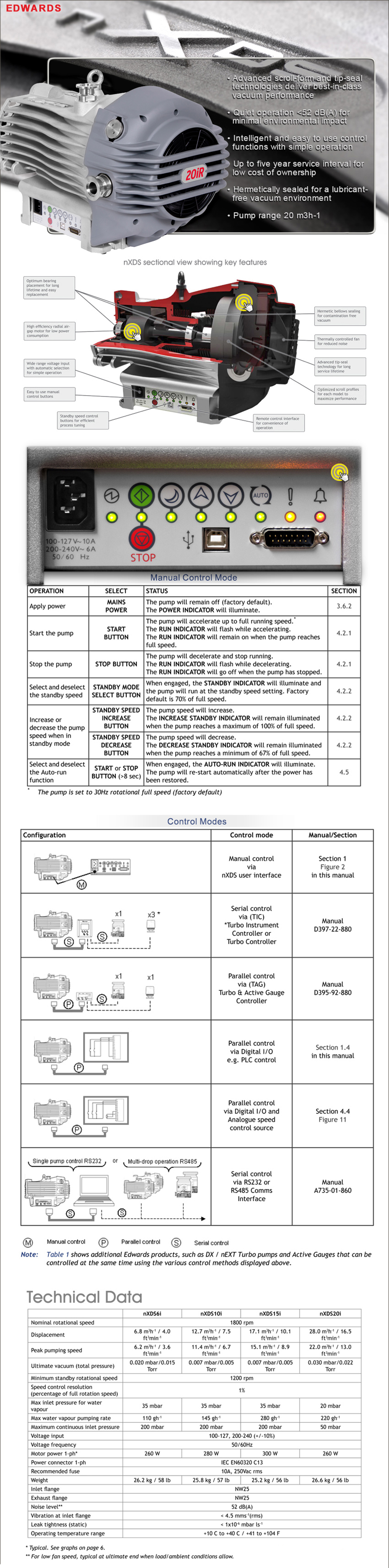

This new nXDS20iR dry scroll pump range from Edwards has exceptional pumping capability, ultimate vacuum performance and state-of-the-art design features. The Edwards nXDS20iR is the best performing pump in its class. The nXDS20iR is up to 20 times quieter than other pumps. Its intelligent control functions and up to five year service interval offer low cost of ownership, making it the small dry pump of choice for today’s most advanced technologies.

The Edwards nXDS-20iR, nXDS 20iR, pumps are truly dry vacuum pumps as all the bearings, with their hydrocarbon lubricant, are isolated from the vacuum space. The nXDS20iR is the next generation in completely oil free, dry scroll pumps and can be used to replace similar sized dry pumps and medium sized oil sealed pumps in a variety of applications. nXDS improves on legacy XDS pumps by offering increased pumping speeds, combined with lower ultimate pressures, lower power consumption and lower noise. Gas ballast allows for pumping of condensable vapours including, water, solvents, dilute acids and bases. nXDS pumps also feature the latest in tip seal technology giving significantly longer life between tip seal changes. Integrated inverter drive with auto sensing voltage input delivers optimized pumping performance globally. nXDS pumps are designed to be completely field serviceable.

R variants (iR models) are available for specialist applications such as gas recirculation, rare gas pumping and recovery or other applications where the dilution of the pumped gas is undesirable, or where sealing is integral to minimising potential gas loss.

Now with an integral pump controller managing the supply of current to a three-phase electric motor in accordance with operating conditions. The controller monitors power and temperature, and will protect the pump in the event of operation under sustained high load or under fault conditions. The controller provides the user interface. The pump may be operated in Manual mode, using the buttons on the interface panel, with a unique feature to control the speed of the pump in Standby Mode to 70% of full speed or with other buttons to increase or decrease pump speed to save wear and tear on tip seals and bearing service life; or a Remote Mode, via serial communications; or a digital and analogue process control (parallel) mode, via the 15-way D-type logic interface connector.

To pump high vapor loads, gas ballast can be delivered into the pump to prevent condensation of the vapor carried by the pumped gases. The logic interface has been designed to support both serial control, parallel control and monitoring, operating through one connector. For serial control either RS232 or RS485 can be selected.

| Technical data | nXDS6iR | nXDS10iR | nXDS15iR | nXDS20iR | |

| Nominal rotational speed |

1800 rpm |

||||

| Displacement | m3h-1(ft3min-1) | 6.8(4.0) | 12.7(7.5) | 17.1(10.1) | 28.0(16.5) |

| Peak pumping speed | m3h-1(ft3min-1) | 6.2(3.6) | 11.4(6.7) | 15.1(8.9) | 22.0(13.0) |

| Ultimate vacuum (total pressure) | mbar(Torr) | 0.020 (0.015) | 0.007(0.005) | 0.007(0.005) | 0.030(0.022) |

| Minimum standby rotational speed | rpm |

1200 |

|||

| Speed control resolution (percentage of full rotation speed) | % |

1 |

|||

| Max inlet pressure for water vapour | mbar | 35 | 35 | 35 | 20 |

| Max water vapour pumping rate | gh-1 | 110 | 145 | 280 | 220 |

| Maximum continuous inlet pressure | mbar | 200 | 200 | 200 | 50 |

| Voltage input | V |

100-127, 200-240 (+/-10%) |

|||

| Voltage frequency | Hz |

50/60 |

|||

| Motor power 1-ph* | W | 260 | 280 | 300 | 260 |

| Power connector 1-ph |

IEC EN60320 C13 |

||||

| Recommended fuse |

10A,250Vac rms |

||||

| Weight | kg (lb) | 26.2 (58) | 25.8 (57) | 25.2 (56) | 25.6 (56) |

| Inlet flange |

NW25 |

||||

| Exhaust flange |

NW25 |

||||

| Noise level** | dB(A) |

52 |

|||

| Vibration at inlet flange | mms-1(rms) |

<4.5 |

|||

| Leak tightness (static) | mbar Is-1 |

<1×10-6 |

|||

| Operating temperature range | °C(°F) |

+10 C to +40 (+41 to +104) |

|||

| * Typical. See graphs on page 6. | |||||

| ** For low fan speed, typical at ultimate end when load/ambient conditions allow. | |||||