Metal 3D Printing & 4D Printing

When printing metal parts, the issue of safety risks of metal powders has to be addressed.

From a practical manufacturing point of view, each stage of metal 3D printing generates a different source of contamination (or substance) which in turn can cause specific hazards.

Metal powders for metal 3D printing, with particle size distributions typically in the tens of microns, can be inhaled into the lungs or alveoli. Low-density titanium, aluminum and their alloys, which are all reactive metals, pose a particularly high risk and must be subject to specific dust concentration limits. Other metal powders, such as steel or other nickel-containing alloys, are classified as carcinogenic, mutagenic and toxic to reproduction under the Dangerous Substances Directive. Prolonged exposure to and inhalation of powder particles poses certain health risks to the operator.

The same applies to the printing process of the components. In addition to the fumes from the melting process, some of which are carried into the filtration system, some of the fumes may be vented to the outside of the printing system, contaminating the indoor environment. In addition to exhaust gases, some inert gases, such as nitrogen and especially argon, are also a source of risk. Equipment maintenance, such as cleaning filter systems, where dust and ash are even finer than metal particles, can cause fires or even explosions due to component stability issues if not handled properly.

Metal powders must be handled with extreme care and, where possible, in a protective atmosphere. Currently, fully enclosed processes are being emphasized by equipment manufacturers, and metal printer brands are realizing fully enclosed operations for all processes from powder filling, cleaning, and even intermediate refilling, and this spatial separation or encapsulation minimizes dust exposure and hazards. In this case, 3D printing glove box becomes a preferred equipment.

3D printing technology, as a cutting-edge, pioneering and very strong emerging technology, has a subversive significance and role in the process transformation of the traditional manufacturing industry and the wide application of new materials.

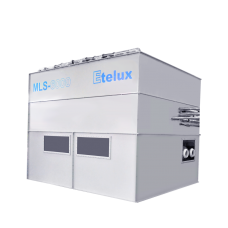

Metal 3D printing inert gas protection system is a set of high-performance, high-quality automatic absorption of water, oxygen molecules super purification protection glove box. It provides a purified working environment needs of closed loop working system, can meet the specific cleaning requirements of the application of inert 1ppm O2 and H2O atmosphere environment.

This is achieved by placing the body of the selective laser dissolution unit inside a sealed chamber that forms a closed loop with a multi-stage dust handpiece and air circulation unit. Argon gas is circulated in this closed loop, and the atmosphere water content in the system reaches less than 1ppm index, and the oxygen content reaches less than 1ppm index, realizing the environment of ultra-high purity working atmosphere.

Processed products can be directly applied, reducing the reprocessing link, is a set of scientific research and development to meet the design of the economic

More than just a “D” in 4D Printing over 3D Printing

At the beginning of the development of 4D printing, it was widely believed that 4D printing was adding a time dimension on the basis of 3D printing. That is, the printed object can adjust itself over time in terms of morphology and structure, and ultimately automatically meet the pre-designed requirements. Scientists believe that the concept of 4D printing should include at least two aspects:

One is that it adds a new time dimension on the basis of 3D printing, while the spatial dimension has also been further expanded to enhance the ability of the printed components to change over time and space.

The second is that under the stimulation of specific external environmental conditions, 4D printing is not only capable of manufacturing components with controllable changes in shape, but also capable of manufacturing components with controllable changes in performance and function.

The so-called 4D printing is accurately described as a material that can automatically deform. In specific conditions (such as temperature, humidity, magnetic field changes, etc.), do not need to connect any complex electromechanical equipment, according to the product design can be automatically folded into the corresponding shape.

The key to 4D printing is “smart materials”. Through the 3D printer equipment, printing deformation material technology called 4D printing. 4D printing is the use of programmable technology, or 3D printing to create a predetermined stimulus, in the external environment changes, 4D printing objects can be with the change of time and environment changes in its shape and performance. The realization of 4D printing on the basis of 3D printing, the continuation of 3D printing, and added the deformation dimension. 4D printing is also considered to be the 3D printing of smart materials.

As human society strides towards the intelligent era, 4D printing technology is timely, it and smart materials to promote each other, common development, has shown good prospects for development in many areas of application.