Leybold TURBOVAC 250i Turbo Vacuum Pump with Conflat 6.0 Inch Inlet , 250 l/s Pumping Speed, Air or Water Cooled. PN: 820061V1000

$8,636.80 $10,796.00

These Leybold TURBOVAC 250i turbomolecular high-vacuum pumps have a pumping speed up to 250 liters per second (l/s), with a Conflat CF 6.0 inch inlet flange, and an ISO KF-16 exhaust foreline flange. These i-series turbo pumps require 24 VDC input power at a maximum of 240 Watts and have an integrated controller. All TURBOVAC i-series turbo pumps include a compact standard interface with RS485, USB and Digital I/O interfaces with 3 status LED’s and the possibility to control one accessory (air cooler, valves, relay box…). All that is needed is a power supply and start/stop logic. Power supplies, forced air or water cooling kits, and an optional remote user interface are available. These 250i turbo pumps have Leybold part number 820061V1000.

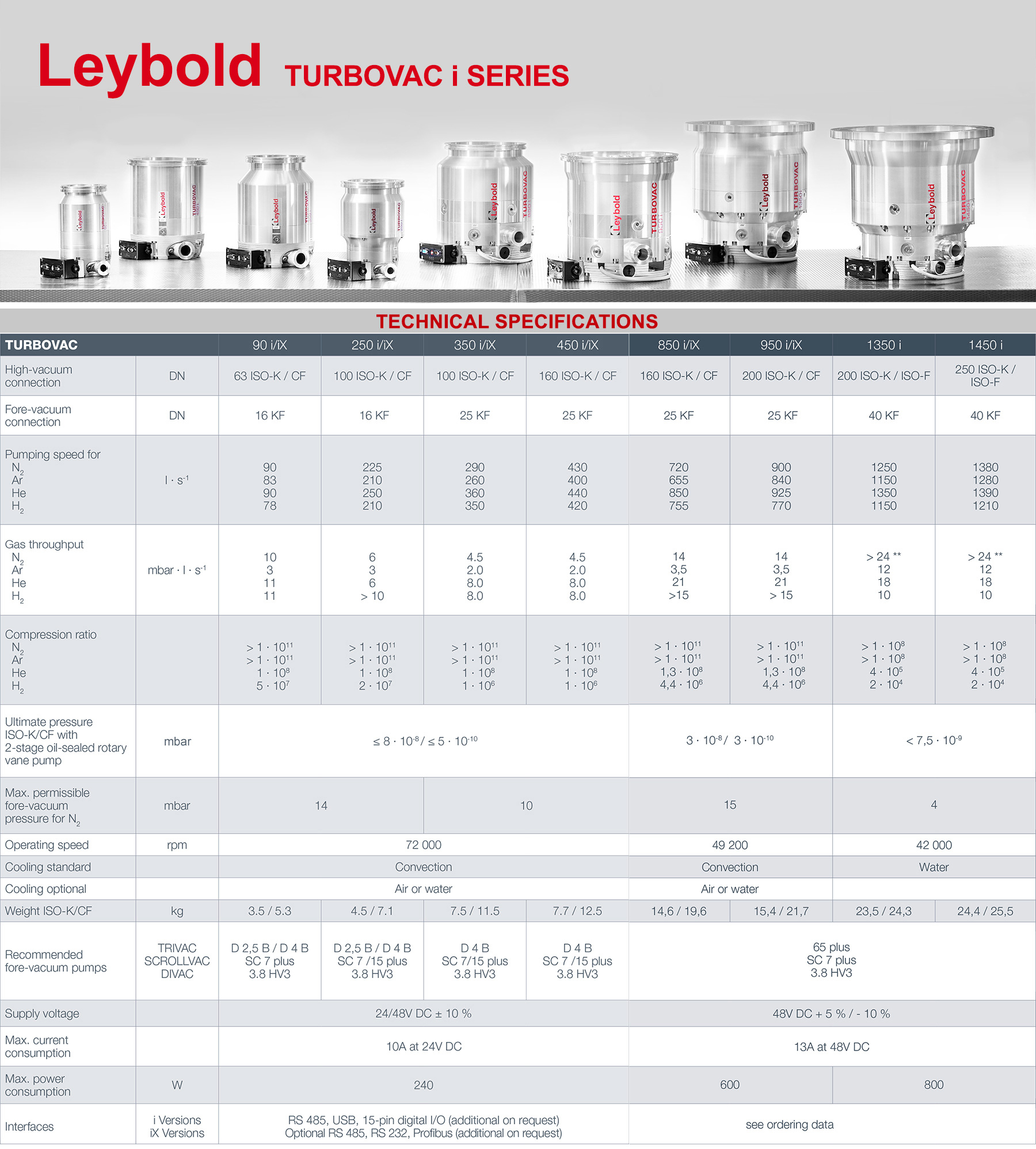

Leybold TURBOVAC 250i Specifications:

·Part Number: 820061V1000

·Inlet Flange: Conflat CF 6.0 inch

·Base Pressure: 5 x 10-10 mbar (3.7 x 10-10 Torr)

·Operating Speed: 72000 RPM

·Operating Position: Any

·Pumping Speed: 250 l/s

·Cooling: Forced Air or Water

·Exhaust Flange: KF-16

·Operating Voltages: 24 VDC

·Maximum Power: 240 Watts

·Compact Standard Interface with RS485, USB and Digital I/O

·One accessory port

·Recommended Roughing Pump: TriVac D4B or ScrollVac SC15

TURBOVAC 250i pumps with a CF flange are true ultra-high vacuum (UHV) pumps with an ultimate pressure into the 10-10 Torr range (if all-metal intake seal gaskets are used and the vacuum chamber is completely clean and baked out). Leybold TURBOVAC 250i turbo pumps with ISO-K flanges are limited (by permeation and outgassing of the rubber/elastomer O-ring seals) to an ultimate pressure in the 10-8 Torr range. The intake flange of these pumps (CF flange only) can be baked up to 100 °C when the turbo is water cooled.

You can choose to power the pump from your instrument’s auxillary power source or purchase either the Leybold TURBO.CONTROL i or TURBO.POWER integra. The TURBO.CONTROL i is a bench top or rack mountable remote user interface/power source, which communicates with the Leybold TURBOVAC i-series pumps through RS-485 and allows for full monitoring and control of the turbo pump. The TURBO.CONTROL i is the most popular option for laboratory and research applications. The TURBO.POWER integra is a local power supply only, which is typically mounted to the bottom of the turbo pump. The Leybold TURBOVAC i-series pumps, with the TURBO.POWER integra power supply mounted under the pump, is a compact low-cost high-vacuum pumping solution that is often integrated into many analytical instrumentation applications, including Electron Microscopy (SEM, TEM) and Focused Ion-beam Systems (FIB).

Designed to offer maximum performance, the Leybold TURBOVAC i-Series turbomolecular vacuum pumps feature a cutting-edge rotor and drag-stage design which provide unparalleled speed, especially for light gases. A wide selection of interface options, housing and flange configurations as well as accessories completes this product line. The unique oil-free hybrid bearing system with maintenance-free ball bearings will boost your productivity and reduce cost of ownership. With a light gas pumping speed of up to 60% above current reference products and compression values around 100 times higher than previous generation products, they are especially suitable for operation with small backing pumps. Your benefits: a considerably smaller vacuum system, lower initial and operating costs along with a more compact footprint.

Performance:

·Industry-leading pumping speed for light gases (up to 60% higher than existing products)

·Optimized rotor diameter to provide maximum pumping performance

Flexibility:

·Vacuum port design flexibility

·Rotatable fore-vacuum port

·Onboard turbo controller

·Only requires power along with start/stop logic

·Optional TURBO.CONTROL i remote user interface

·Compact design with optional TURBO.POWER integra

Installation, operation and control:

·Integrated 24/48V DC drive electronics to avoid expensive cabling

·Widest range of communication interfaces: USB, RS485, and remote 15 pin digital I/O as standard options

·Highly efficient motor

·Thermal isolation by design for optimized cooling of bearing and improved pump lifetime

·Innovative shaft support system reduces vibration

·Maintenance free upper passive magnetic bearing

·Oil free, lifetime lubricated, lower mechanical ceramic ball bearing is field-replaceable

The Leybold TURBOVAC i-series turbo pumps are plug and play. They are simple and easy to install, operate and control, thanks to their flexible product design, integrated electronics, and a wide range of communication interfaces. They offer superior reliability due to an innovative pump design and the unique oil-free hybrid bearing concept with maintenance-free ball bearings available in the market today. The innovative shaft support system reduces vibration, noise, mechanical stress, and alleviates potential negative impact on vibration sensitive applications. Optimized cooling of the bearings is ensured through thermal isolation and a highly efficient motor. The pump is also equipped with a purge port to protect the bearings from critical gases and particles. As a result, the up-time and lifespan of the pump as well as your productivity are increased considerably. In combination with low costs of ownership, your vacuum system will be more efficient than ever.

Typical Turbo Pump Applications include:

·General clean pumping applications

·Scanning Electron Microscopes – SEM

·Beam lines and high energy physics

·Mass Spectrometry

·Electron Microscopy

·Sample Preparation

·Research and Development

·High Energy Physics

·Industrial

·Semiconductor

·Coatings

·Surface Science Instruments

The operating instructions manual and Leybold i-series TURBOVAC product brochures are available in the downloads.