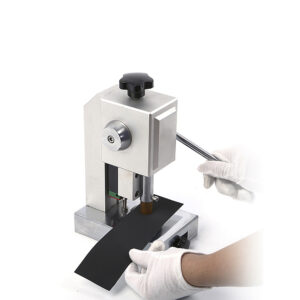

Quality Coin Cell Manual Hydraulic Sealing Machine for Button Cell Assembly

* Dimensions: 223mm x 170mm x 325mm

* Weight: 25kg.

Please contact [email protected] to get the delivery charge of the product.

$950.00 $1,500.00

Description:

It is applied to the production of samples for the research and development of battery materials in the laboratory for button batteries and capacitor scientific research sealing, and can also be used for small batch trial production in factories. It adopts electric mode and saves effort. It can also be used for dry powder tableting, wet powder tableting, compression molding, riveting and other operations with different molds. A set of molds for CR20 series button batteries such as CR2032, CR2025, CR2016, etc.

Features:

*The lower mold is limited by a high-precision positioning ring to control the height of the battery packaging, so as to avoid excessive and unstable packaging pressure, which may cause damage to the sealing cup.

*The inner ring of the upper mold sealing cup is equipped with a screw spring centering mechanism to ensure that in case the battery is stuck and cannot be removed during sealing, the button battery can be forced out by twisting the top screw.

*Built-in safety overflow oil valve, the pressure can be adjusted according to needs, and the upper pressure limit can be set to prevent damage caused by excessive pressure caused by misoperation, ensuring the safety of the machine.

*Built-in pressure gauge can observe and accurately control the size of the sealing pressure.

*Using hydraulic drive, the pressure can reach 8T, the battery seal has no vibration and no leakage.

*Specially designed hydraulic structure, labor-saving operation.

*Precision mold design ensures accurate and reliable sealing forming, solid steel structure design, stable and safe use.

*Small size, easy to operate, can be placed in a glove box for operation.

*Beautiful appearance, easy maintenance, small size, convenient operation, accurate molding, etc.

Technical parameter:

*The operating force of the hand crank is less than 5kg;

*The pressure gauge of the normal button battery packaging pressure is about 80~100kg/cm2. The machine has been adjusted before leaving the factory. If you need more pressure (pressure 200kg/cm2 about 8 tons), please consult the manufacturer. Can be adjusted later;

*Mold material imported from Japan;

*The mold is limited by a high-precision positioning ring to control the height of the battery packaging, in case the packaging pressure is too large and unstable, which may cause damage to the battery sealing.

*It has the function of preventing short circuit of battery sealing.

*Structural material: high-strength chromium steel, the surface will never rust after environmental protection plating and spraying.

*Dimensions: 225mm X 180mm X 335mm

*Weight: 30kg.