Subtotal: $2,150.00

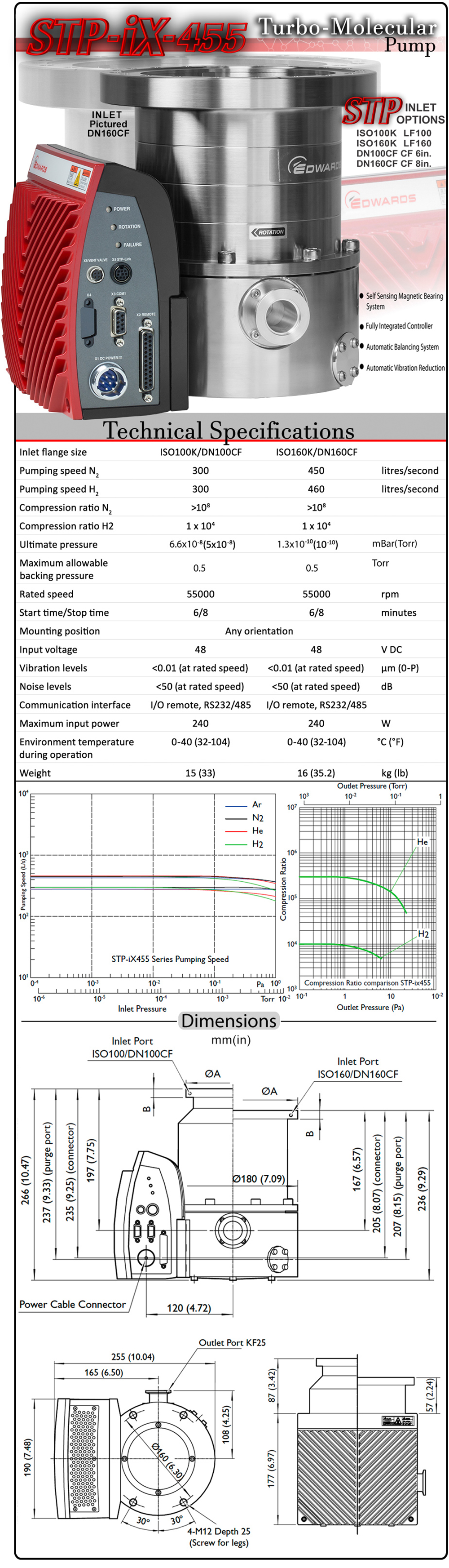

Edwards STP-iXL455 5-axis Magnetic Bearing Turbo-Molecular Pump ISO160K, LF160 Inlet

●Self Sensing Magnetic Bearing System

●Fully lntegrated Controller

●Automatic Balancing System

●Automatic Vibration Reduction

$20,064.96 $25,081.20

The STP-iXL455 turbo-molecular pump utilizes a magnetic bearing and motor drive system and has an ultimate pressure of 1.3×10-10 Torr (8 in. O.D. conflat inlet). The “L” in this version has even lower noise and vibration performance than the standard model and also has different dimensions, see STP-iXL455 Instruction Manual Below. With its multi-axis magnetic bearing system contact between the rotor and the remainder of the pump is completely eliminated, effectively producing an unparalleled level of vibration and heat reduction. No frictional contact in the STP-iXL455 also reduces wear and enables it to run virtually maintenance free for years. With an integrated controller eliminates the need for a conventional rack mounted controller. This STP-iXL455 turbo pump runs so cool it needs no water for cooling. No need for interconnecting cables but you will need a 48VDC external power supply source not provided. (model with power supply is available on this website).

The STP-iXL455 has a built in automatic balancing system (ABS), a key feature of 5-axis magnetic drive technology. Sensors in the pump detect imbalance in the rotor motion and respond by adjusting the bearings magnetic fields to permit the rotor to spin on its own inertial axis, reducing vibration sent to the inlet flange. This function of the STP-iXL455 works at all rotational speeds to ensure pump safety. All STP series pumps have dry lubricated radial and axial mechanical bearings as backup safety bearings. In the event of total failure of the magnetic bearings, these mechanical bearings will support the rotor and protect the pump.

The STP-iXL-455 can be connected directly to a terminal using a serial port and the STP-link Monitoring Software. The Software Displays, Rotational Speed, Motor Status, Temperature, Rotor balance status & Magnet bearing current.

The STP-iXL455 can be used for a variety of applications including but not limited to:

-Plasma etch (chlorine, fluorine and bromine chemistries) for metal (aluminum), tungsten and dielectric (oxide) and polysilicon

-Electron cyclotron resonance (ECR) etch

-Film deposition CVD, PECVD, ECRCVD, MOCVD

-Sputtering

-Ion implantation source, beam line pumping end station

-MBE

-Diffusion

-Photo resist stripping

-Crystal/epitaxial growth

-Wafer inspection

-Load lock chambers

-Scientific instruments: surface analysis, mass spectrometry, electron microscopy

-High energy physics: beam lines, accelerators

-Radioactive applications: fusion systems, cyclotrons

GE VeriDri Moisture Transmitter -110 Degree Centigrade

GE VeriDri Moisture Transmitter -110 Degree Centigrade